Introduce the prevention of hydrogen embrittlement in spring steel. Spring steel and its alloys produce hydrogen due to comprehensive or local corrosion in pickling solutions. The newly generated hydrogen enters the metal and accumulates at internal defects or stress concentration points, causing fracture. This type of fracture occurs in various spring steels (especially high-strength spring steels) and various stainless spring steels and their alloys. The hydrogen embrittlement caused by acid pickling of spring steel will bring trouble to future processing. To prevent hydrogen embrittlement of spring steel, the following methods can be adopted.

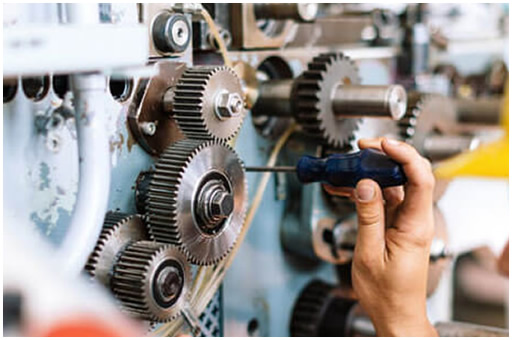

A spring is a mechanical component that works by utilizing elasticity. Generally made of spring steel. Used to control the movement of mechanical components, mitigate impact or vibration, store energy, measure the magnitude of force, etc., widely used in machines and instruments. The types of springs are complex and diverse, classified by shape, mainly including spiral springs, spiral springs, plate springs, etc. But how much knowledge do you have about the use and maintenance of springs?

The surface treatment technology of spring Dacromet and chromium free zinc aluminum coating is a new concept of surface treatment developed to meet the VOC regulations and environmental requirements of the automotive industry in various countries around the world. As an updated product of zinc chromium coating (Dacromet), chromium free zinc aluminum coating has been widely recognized and accepted by the automotive manufacturing industry. Currently, there are only a few products that have achieved industrialization of chromium free zinc aluminum coatings: one is the Geomet coating launched by MCI in the United States, and the other is the Delta coating launched by Delta in Germany

How to distinguish the size and length of steel? How do we know the size of the most commonly used steel in our daily lives? We have springs such as small springs, medical springs, antenna springs, etc. They have sizes such as outer diameter, inner diameter, and length, and steel also has its own name. Here are a few points to distinguish the ethnic sizes of steel.

Introduce the current development status of spring materials and the advancement of spring application technology, which has raised higher requirements for materials. Mainly to improve fatigue life and anti relaxation performance under high stress; Secondly, according to different purposes, it is required to have corrosion resistance, non-magnetic properties, conductivity, wear resistance, heat resistance, etc. To this end, in addition to developing new varieties of spring materials, beneficial results have also been achieved in strictly controlling chemical composition, reducing non-metallic inclusions, and improving surface quality and dimensional accuracy.

Introduce several major drawbacks of the current spring industry. Advanced enterprises in China have complete production lines and sophisticated testing equipment imported from abroad, and well-developed enterprises have also purchased some key equipment from Germany, Japan, Italy, and Taiwan, such as CNC spring coiling machines, double disc spring grinding machines, and through shot blasting machines. Domestic equipment has also been updated, but these enterprises have not yet achieved production line production.

What are the excellent properties and high strength that spring steel should possess? To improve the ability of springs to resist fatigue failure and relaxation, spring materials should have high yield strength and elastic limit, especially a high yield strength ratio (yield strength/elastic limit). In general, the elastic limit of materials is proportional to the yield strength, so spring designers and manufacturers always hope that materials have high yield strength. The tensile strength and yield strength of spring materials are relatively close, but the tensile strength is easier to measure than the yield strength

Introduce the products produced from stainless steel wire and stainless steel sheet. According to the force properties, springs can be divided into tension springs, compression springs, tension springs, and torsion springs; According to their appearance, they can be divided into disc springs, ring springs, plate springs, coil springs, truncated cone spiral springs, and torsion bar springs. The popular cylindrical spring is the most widely used due to its simple production and the ability to be made into various types according to the load situation, as well as its simple structure.

Dongguan Zhixiang Spring Co., Ltd. is a manufacturer and wholesaler of precision springs, pressure springs (compression springs), tension springs (tension springs), torsion springs (torsion springs), special-shaped springs, battery springs, non-standard springs, and various hardware components.

A professional spring manufacturer that introduces professional technology. In the next 5-7 years, China's automotive industry will enter a high-speed growth stage, with an annual growth rate of 15% to 25%. In 2003, the demand for suspension springs is expected to approach 10 million pieces, and the demand for stabilizer bars is 1.6 million pieces. The rapid development of the automotive industry has had a significant driving effect on the spring industry, making it the largest user of the spring industry and attracting the attention of foreign spring peers. In addition to a few foreign companies that entered the Chinese market ahead of others